MILANESE CONSORTIUM PRODUCTION ARTISAN

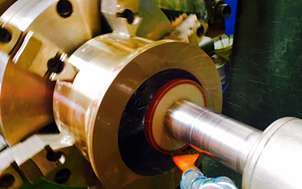

Machining of mechanical turning

Each process has its own peculiarities and complications and each one must be addressed with the most appropriate technologies and machines.

In our case, having to do with limited numbers, i.e. with lots from 1 to 100 items, it does not make sense to move towards the high removal or tool change speeds, now allowed by the most advanced machine tools, because saving 5 seconds on the the execution of a piece that often and willingly has to stay in the car for 5 hours does not change our life, while it changes it, too, and for those who have to make tens of thousands of pieces.

Consequently what is important for Co.m.ar.p is the preventive study of the process to be adopted so that all its phases are carried out in an optimal way, which can happen if, in addition to reliable and technologically advanced machines, you have qualified and experienced staff on the shoulders. Turning is mainly used to make pieces ascribable to solids that can have various characteristics such as holes, threads, grooves, various diameter steps, tapers and shaped surfaces.

WE CAN MAKE PIECES UP TO SIZE OF:

Materials

Then the materials we use for mechanical processing

Range of machines

Our turning department is composed of traditional and CNC machinery, also with motorized turret, with the possibility of turning from a minimum of 30mm up to a maximum of 450mm in diameter, with a maximum length of 1500mm, with a wide range of workable materials, including: C40, C45, A105, LF2, F22, F51, F91, XM19, F6A, INCONEL 625, INCONEL 718 and many others.

Parts obtained from traditional and small and medium series CNC turning, small parts obtained from bar with automatic and CNC machines.