MILANESE CONSORTIUM PRODUCTION ARTISAN

An innovative welding process

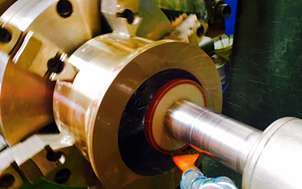

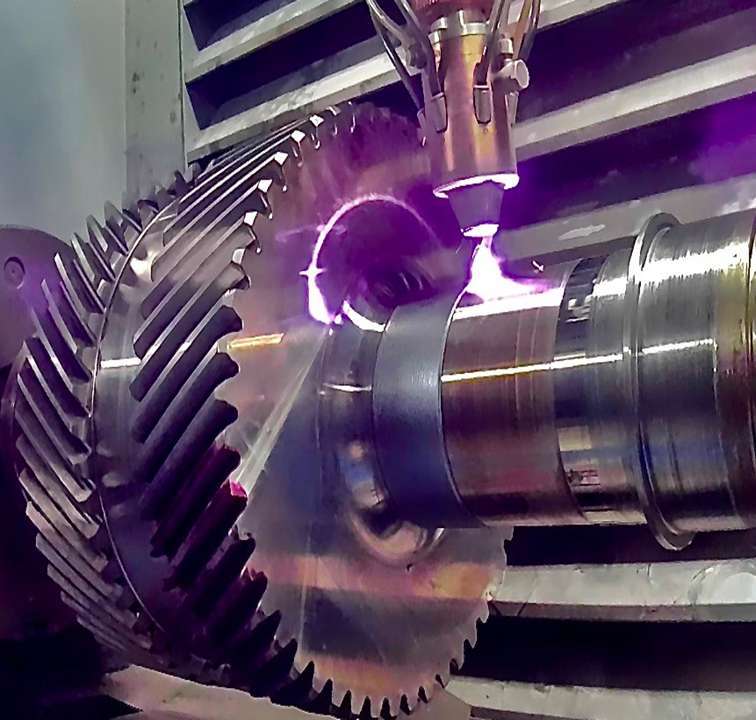

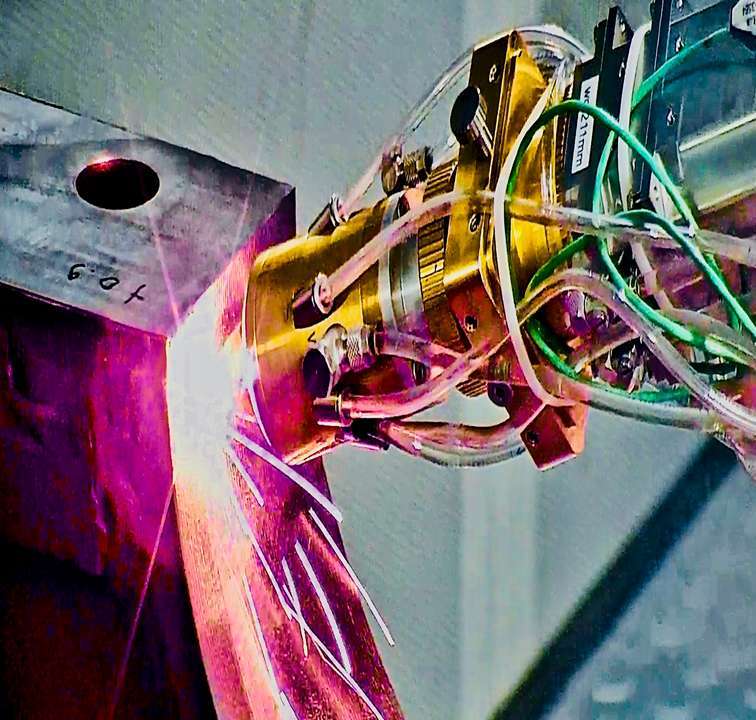

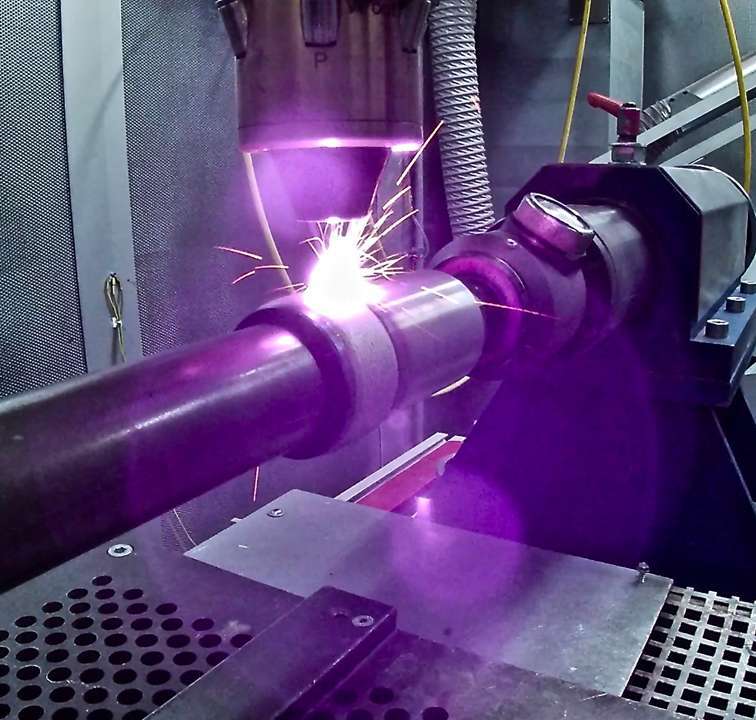

What is laser cladding? It is an innovative welding process that uses the laser source to join the coating material to the base one. This technology is applied for the protection and regeneration of mechanical components such as: shafts, spindles, rods, cylinders, rotors, impellers, blades, bearings, valves belonging to the sectors: energy, oil & gas, iron and steel, hydraulic, agricultural, paper, naval, aeronautical.

Advantages

- Low heat transfer to the component, resulting in minimal deformation

- Metallurgical adhesion between the coating and the substrate, with a minimum dilution

- High-density coatings and homogeneous microstructure that guarantee a finish reduced to a minimum

- High process stability, this allows for easy automation

- Possibility of combining laser cladding with other Thermal Spray processes

- Very high energy efficiency and deposit yield

The layout of our plant and the high automation with the 7-axis robot allows us to cover large components:

D I A M E T E R : 2 M E T E R S

L E N G T H: 6 M E T E R S

W E I G H T: 5 0 Q U I N T A L S

Depositable materials

aluminum, copper, bronze, white metal

- IRON-BASED POWDERS: AISI 308 – 316 – 431 – 410 FeCr V15 – FeCr V12

- NICKEL BASED POWDERS:Inconel 625 – Hastelloy C276 – NiBSi-22- NiCrBSi -30-40-50-60 HRC

- COBALT-BASED POWDERS: Stellite 1 – 6 -12 – 21 T400 T800

- CARBIDE REINFORCED POWDERS: NiBSi / WSC NiCrBSi / FTC and many other blends on request …

HARDNESS FROM 20 HV UP TO 3000 HV

High corrosion resistance for over 5,000 hours in salt spray

Materiali

In seguito i materiali che usiamo per le lavorazioni meccaniche

AISI 316 | AISI 316L

AISI 316 | AISI 316L

Specifiche

Lega di acciaio inox austenitica composta da un tenore di cromo tra il 16% ed il 18%, di nichel tra l’11% e il 14% e di molibdeno tra il 2% ed il 3%. Si ricava a partire dall’acciaio X5CrNi1810 con l’aggiunta del 2,5% di molibdeno, utile per migliorare la resistenza alla corrosione elettrolitica (pitting) da cloruri. Quest’ultima caratteristica lo rende adatto all’esercizio in ambienti interessati da acqua di mare e nelle applicazioni navali.

Il 316L ha tenore di carbonio inferiore allo 0,035% (il 316 ammette fino a 0,080%) utile ad impedire la precipitazione dei carburi di cromo e quindi la corrosione.

AISI 303 | AISI 304 | AISI 410 | AISI 420

AISI 303 | AISI 304 | AISI 410 | AISI 420

Specifiche

Gli acciai inox (o acciai inossidabili) sono leghe di ferro caratterizzate, oltre che dalle proprietà meccaniche tipiche degli acciai al carbonio, da una notevole resistenza alla corrosione, specie in aria umida o in acqua dolce.

Tale capacità di resistere alla corrosione è dovuta alla presenza di elementi di lega, principalmente cromo, in grado di passivarsi, cioè di ricoprirsi di uno strato di ossidi sottile e aderente, praticamente invisibile, di spessore pari a pochi strati atomici (dell’ordine dei 3-5 × 10−7 mm), che protegge il metallo, o la lega, sottostante dall’azione degli agenti chimici esterni.

DUPLEX | SUPERDUPLEX

Duplex | SUPERDUPLEX

Specifiche

Gli acciai austeno-ferritici, detti anche duplex, presentano una struttura mista di austenite e di ferrite. Si tratta di un acciaio al cromo ibrido: il tenore di cromo va dal 18 al 26% e quello di nichel dal 4,5 al 6,5%, quantità insufficienti per determinare una struttura microcristallina totalmente austenitica (che quindi rimane in parte ferritica). Quasi tutte le sue varianti contengono fra il 2,5 e il 3% di molibdeno.

TITANIO gradi 2,5,6

TITANIO gradi 2,5,6

Specifiche

È un elemento metallico che è ben conosciuto per la sua resistenza alla corrosione (quasi quanto il platino) e per il suo alto rapporto resistenza/peso. È leggero, duro, con una bassa densità. Allo stato puro è abbastanza duttile, lucido, di colore bianco metallico.Il titanio è resistente come l’acciaio ma il 40% più leggero, pesa il 60% in più dell’alluminio ma con una resistenza doppia. Queste proprietà rendono il titanio molto resistente alle forme usuali di fatica dei metalli.

MONEL 400 | MONEL K500

MONEL 400 | MONEL K500

Specifiche

Il monel è una lega metallica formata da nichel e rame. La lega Monel 400 principalmente composta di nichel (fino al 67%) e dal rame al 32%, presenta una resistenza meccanica relativamente elevata, una buona resistenza alla corrosione e una buona saldabilità.

La lega Monel K500 si ottiene aggiungendo alla lega monel alcune piccole quantità di Alluminio e Titanio. La sua composizione è: Nichel 60%, Rame 30%, Alluminio 2,7%, Titanio 0,5%. Tale lega presenta una resistenza meccanica doppia rispetto alla Monel 400.

NITRONIC 50,60

NITRONIC 50,60

Specifiche

Acciaio inossidabile fortemente legato che unisce buona resistenza e resistenza alla corrosione a un’eccellente resistenza all’usura generica e da attrito.

INCOLOY 825

INCOLOY 825

Specifiche

È una lega di nichel, cromo, ferro con aggiunte di molibdeno, rame e titanio, con eccezionale resistenza alla corrosione molti ambienti aggressivi. È altamente resistente alla corrosione. Ha un alto contenuto di nichel, sufficiente per resistere alla corrosione da ioni cloruro, e una struttura austenite molto stabile.

I livelli di molibdeno e rame consentono alla lega di resistere agli agenti riducenti e agli acidi.

RAME

RAME

Specifiche

Utilizzato principalmente per la componentistica elettrica, grazie ad una conducibilità altissima, sia elettrica che termica

ALLUMINIO

Alluminio

Specifiche

È un metallo leggero, ma resistente, con un aspetto grigio argento a causa del leggero strato di ossidazione, che si forma rapidamente quando è esposto all’aria e che previene la corrosione in quanto non solubile.

L’alluminio ha un peso specifico di circa un terzo dell’acciaio, o del rame; è malleabile, duttile e può essere lavorato facilmente; ha una eccellente resistenza alla corrosione e durata. Inoltre non è magnetico, non fa scintille, ed è il secondo metallo per malleabilità e sesto per duttilità.

OTTONE

OTTONE

Specifiche

È una lega ossidabile formata da rame (Cu) e zinco (Zn).

La lavorabilità alle macchine utensili delle leghe binarie rame-zinco è buona, ma la tenacità provoca la formazione di trucioli molto lunghi; allora si aggiunge del piombo (Pb) che, insolubile ed estraneo alla struttura cristallina, si disperde ai bordi dei grani: così i trucioli diventano corti o addirittura polverosi e gli utensili subiscono un’usura e un riscaldamento minori, con conseguente miglioramento della qualità e della velocità della lavorazione. Gli ottoni al piombo sono denominati anche ottoni secchi.

GHISA

ASTM A105

ASTM A105

Specifiche

Acciaio di largo utilizzo per impieghi strutturali, in maniera specifica per flange ed altri elementi per montaggi, valvole e componentistica per sistemi a pressione. E’ normalmente fornito sotto forma di barre laminate e forgiate.

BRONZO

BRONZO

Specifiche

Questa lega composta principalmente di rame, viene arricchita con stagno fino all’8-9%, dando luogo a leghe con buone caratteristiche meccaniche e grande resistenza alla corrosione: queste leghe sono ancora lavorabili plasticamente e si possono laminare, estrudere, forgiare, stampare e trafilare. Aumentando ulteriormente il tenore di stagno, la durezza raggiunge livelli tali da consentire solo pezzi ottenuti per fusione, chiamati anche getti.

A livello industriale si arriva a produrre bronzi con tenori fino al 30% di stagno.

HASTELLOY C22

HASTELLOY C22

Specifiche

L’Hastelloy C-22 è una lega nickel-cromo-molibdeno-tungsteno molto versatile, che ha una resistenza alla corrosione migliorata rispetto alle leghe nickel-cromo-molibdeno (leghe C-4 e C-276). La lega C-22 infatti presenta un ottimo comportamento nei confronti di ambienti promotori di pittting e cervice corrosion, inoltre presenta una notevole resistenza allo stress corrosion cracking. L’Hastelloy C-22, grazie alla elevata presenza del cromo, rispetto alle altre leghe della serie C, ha anche un’ottima resistenza agli agenti ossidanti in soluzione come l’acido nitrico, gli ioni ferrici e gli ioni cloro, mentre la presenza del molibdeno garantisce buona resistenza agli agenti riducenti.

ALLOY

ALLOY

Specifiche

Progettata specificatamente per resistere all’acido solforico, offre un’eccellente resistenza alla corrosione. Grazie ai suoi livelli di nichel, cromo, molibdeno e rame, questa lega è l’ideale per gli utilizzi negli ambienti corrosivi.