MILANESE CONSORTIUM PRODUCTION ARTISAN

Cold stamping, metal and sheet shearing

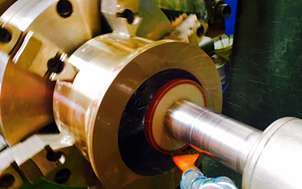

Co.m.ar.p carries out blanking of drawing parts, drawn, reworked with block or step molds of our construction, or supplied by the customer.

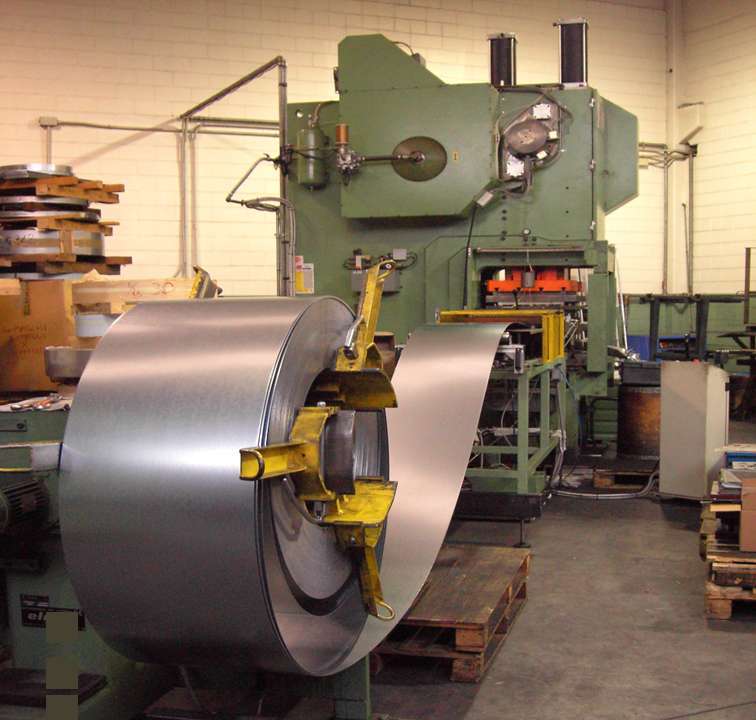

With the term blanking Comarp means the entire “department” dedicated to the cold stamping of sheet metal. Over the years, sheet metal working has become increasingly important in the metalworking industry thanks to the high number of products that can be made with these processes. They range from car bodies to the household appliance sector, from furniture to organs for fine mechanics, etc.

All molding operations take place with the help of machinery (presses and shears) and equipment (molds), which have the function of transferring the shearing or deformation effort on the sheet to be processed.

Sheet shearing is a mechanical process that is almost always carried out in the cold and is particularly suitable for large quantities of production, given its low cycle time and consequently its reduced cost.

Molding is the set of operations carried out to create shapes (holes, slots, notches) and shapes to create the desired shapes by impressing permanent deformations on the sheet. Molding is normally carried out from sheet metal or tape and can include multiple processing stages.

At Comarp we are able to carry out all these processes.

Among the small metal parts that Comarp can produce within its metal blanking department there are: sheet metal hinges, details for locks and appliances, keys, accessories for musical instruments, springs, drawn bushes, buckles, stainless steel objects, in brass, aluminum, harmonic steel and other metal alloys.

Materials

Then the materials we use for mechanical processing

Machine park

We have supplied the 20T mechanical and hydraulic presses. at 160T. Of course, the pressure to print or cut varies according to the tonnage of the machine or the thickness of the detail. The precision and consequent molding quality are guaranteed thanks to periodic checks and maintenance after each processing, in order to comply with procedural standards.

This, together with the competence of our technicians, lowers the non-compliance rate which is below 0.001%.